Instrument Inspection Manual

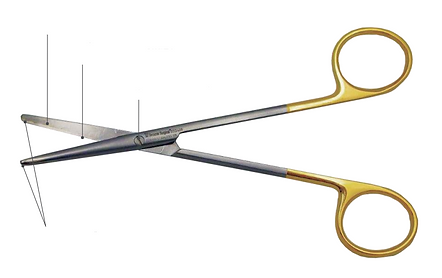

Detailed instrument inspection: Scissors

1 Chips, pitting or cracks

3 Loose or worn screw

2 Dull cutting edge (use testing strip)

4 Bent or broken tips

Scissors Inspection

1. Chips, pitting or cracks

Inspect the scissors' cutting edge for any nicks or "holes" from pitting.

Scissors with these defects cannot be repaired.

2. Dull cutting edge

Use of Securos Testing Strips. Scissors should be sharpened if they catch

on the testing strip material.

3. Loose or worn screw

A loose or worn screw will make the scissors feel "sloppy" and the cutting

edges will not pass together properly. A small crack could develop close

to the screw. A cracked, loose, or worn screw can be repaired.

4. Bent or broken tips

Open and close the instrument. Bent tips will rub noticeably at the tip.

Bent tips may possibly be repaired. Broken tips cannot be repaired.

Detailed instrument inspection: Needle holder

1 Cracked box lock

2 Loose box lock

3 Ratchet fit

4 Cracked jaws or worn inserts

Needle holder inspection

1. Cracked box lock

Inspect box lock closely for cracks. Cracks reduce the integrity of the instrument. Visible cracks cannot be repaired.

2. Loose box lock

Open the instrument and hold one ring handle in each hand. Gently move one handle up and down; there should be minor movement in the box lock, but it should not be loose. A loose box lock can be repaired.

3. Ratchet fit

The instrument should stay tightly locked and properly aligned in the first ratchet position. Misaligned ratchets can be repaired.

4. Cracked jaw or worn inserts

A crack in the jaw appears with a distinct bend and a clear break behind the insert. Cracked jaws cannot be repaired. For Tungsten Carbide Needle Holders, a cracked or worn insert can be replaced. Close the instrument and hold it up to a light. If light is passing between the insert and the jaw, the insert needs to be replaced.

Detailed instrument inspection: Forceps

Forceps inspection

1. Jaw alignment

Securely close the instrument and inspect the jaw alignment. Forceps with teeth: open and close the instrument to feel if the teeth are engaging each other. Misaligned jaws can be repaired.

2. Cracked box lock

Inspect box lock closely for cracks. Cracks reduce the integrity of the instrument. Visible cracks cannot be repaired.

3. Loose box lock

Open the instrument and hold one ring handle in each hand. Gently move one handle up and down; there should be minor movement in the box lock, but it should not be loose. A loose box lock can be repaired.

4. Ratchet fit

The instrument should stay tightly locked and properly aligned in the first ratchet position. Misaligned ratchets can be repaired.

5. Worn serrations or broken teeth

Inspect the jaws for worn serrations or broken teeth. Forceps with worn serrations or broken teeth cannot be repaired.

3 Loose box lock

1 Jaw alignment

2 Cracked box lock

5 Worn serrations or broken teeth

4 Ratchet fit